Contact persons: Nicoleta-Mihaela FLOREA, Andreea RADU

The laboratory was developed to support the nuclear physics experiments performed mainly at the IFIN-HH 9 MV Tandem Accelerator

or at other international research facilities in the frame of scientific collaborations

(CERN, IN2P3, TUM, IKP, JINR, etc).

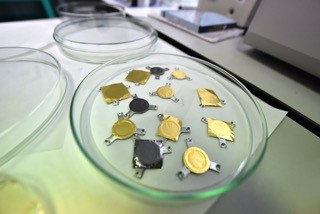

The laboratory provides thin films of various thicknesses from several tens of μg/cm2 to several hundreds of mg/cm2 made from both naturally occurring materials and stable enriched isotopes.

Such thin films (called “targets”) are dedicated for different types of nuclear structure experiments: nuclear structure and lifetimes measurements

of excited nuclear states using γ-ray spectroscopy techniques (Doppler shift attenuation, plunger, and fast-timing), nuclear structure studies

using the activation technique, cross-section measurements of interest for nuclear astrophysical processes, etc.

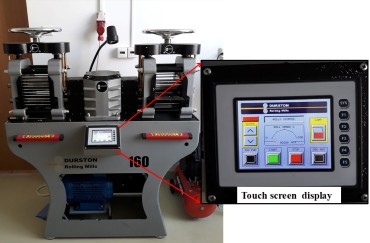

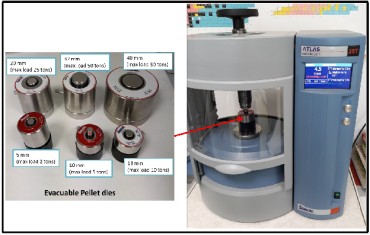

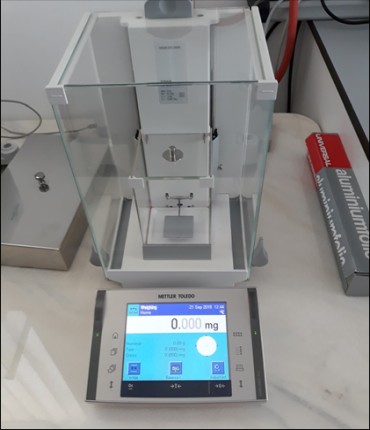

To assure good target quality the laboratory includes state-of-the-art equipment used for thin-film fabrication technology and consist

of Physical Vapor Deposition (PVD) and mechanical rolling techniques.